In December 1999, the China National Aero-Technology Import and Export Corporation (CATIC) announced a $345 million contract with the Egyptian Defence Department to export the K-S aircraft and its production line; the K-S had already been exported to several countries such as Pakistan, Myanmar and Zambia.

In December 1999, the China National Aero-Technology Import and Export Corporation (CATIC) announced a $345 million contract with the Egyptian Defence Department to export the K-S aircraft and its production line; the K-S had already been exported to several countries such as Pakistan, Myanmar and Zambia.

Since July 2000, when the contract to jointly produce a total of 80 K-SE jet trainers within five years was signed, more than 200 Chinese technicians and workers have been sent to Cairo, where they worked around the clock with their Egyptian counterparts. The first two Egyptian K-8Es rolled off the assembly line in late June 2001, carrying a 23mm gunpod under the fuselage and powered by an Allied Signal engine. The aircraft factory AOI/ACF (Arab Organisation for Industrialization/Air Craft Factory) at Helwan El Hammamat, Helwan, is in the southern suburbs of Cairo and had a target of completing two planes every month. Chinese and Egyptian senior officials hailed the production of the first K-SE jet training aircraft as a good start to their aircraft co-production project.

K-8E, an Egyptian version of the K-8 series, a tandem-seated, all-metallic, low-wing and fuselage-side air intake jet training aircraft, is a new generation of the K-8 jet trainer which was jointly developed by China and Pakistan in the 1990s and won acclaim for its excellent demonstration flights in many overseas aircraft shows, including the 1999 Paris Air Show; each aircraft costs approximately $20 million. K-8, which stands for Karakoram-8, is a two-seat advanced training jet and light air-to-ground attack aircraft. It has an impressive specification - crew 2 (trainer and trainee); engine: Garrett TFE-731-2A-2A turbo fan; wing Span 9.36m; length 11.06m; maximum speed 702 mph - and is fitted with a Martin-Baker EP10LW ejection seat.

The co-production of the K-8E in Egypt consisted of three phases. In the first phase China supplied all the main parts of the aircraft for the assembly of a complete aircraft. By the end of the programme Egypt will have the capability to manufacture the major parts and to assemble the planes independently. This, in the words of Egyptian Air Force officers, will help to re-establish the nation's aviation industry, which was obstructed in the 1970s for a variety of reasons.

The K-8E co-production project will also help to consolidate "the strategic co-operative relationship" set up by the two nations when President Jiang Zemin visited Egypt in 1999, according to a high-ranking official of the China National Aero-Technology Import and Export Corporation, which represents the Chinese side for the operation of the project. "The project is a fine example of Sino-Egyptian trade and economic cooperation based on friendship, equality, trust and mutual assistance," a Chinese official said.

The K-8E co-production project will also help to consolidate "the strategic co-operative relationship" set up by the two nations when President Jiang Zemin visited Egypt in 1999, according to a high-ranking official of the China National Aero-Technology Import and Export Corporation, which represents the Chinese side for the operation of the project. "The project is a fine example of Sino-Egyptian trade and economic cooperation based on friendship, equality, trust and mutual assistance," a Chinese official said.

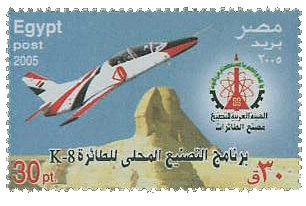

On December 12, 2005, the initial batch of 80 aircraft was produced on target, successfully completing the first Sino-Egyptian contract on joint aircraft-manufacture, and it is this that the stamps celebrate. "As the 80th K-8E aircraft is being delivered to the Egyptian Air Forces, today we are celebrating a milestone in joint Sino-Egyptian co-operation in aircraft-manufacturing, and now it has been authorised to produce as much as 97.4 per cent of the components of the aircraft," said Ibrahim Yunis, chairman of the AOI/ACL aircraft-manufacturing company.

The factory is no stranger to the manufacture of foreign-designed planes The Helwan Aircraft Factory was opened during 1950-51, to produce the British De Havilland Vampire jet fighter under licence (this programme was cancelled during 1952). It has also made parts and components of the Mirage 2000 as well as the Falcon 50 and the Brazilian Tucano. It also successfully produced the indigenous-designed Al-Gomhuria, a basic flight trainer, of which about 200 were made

During the mid-1970s this facility became part of the Arab Organization for Industrialization (AOI), whose logo also appears on the stamps.